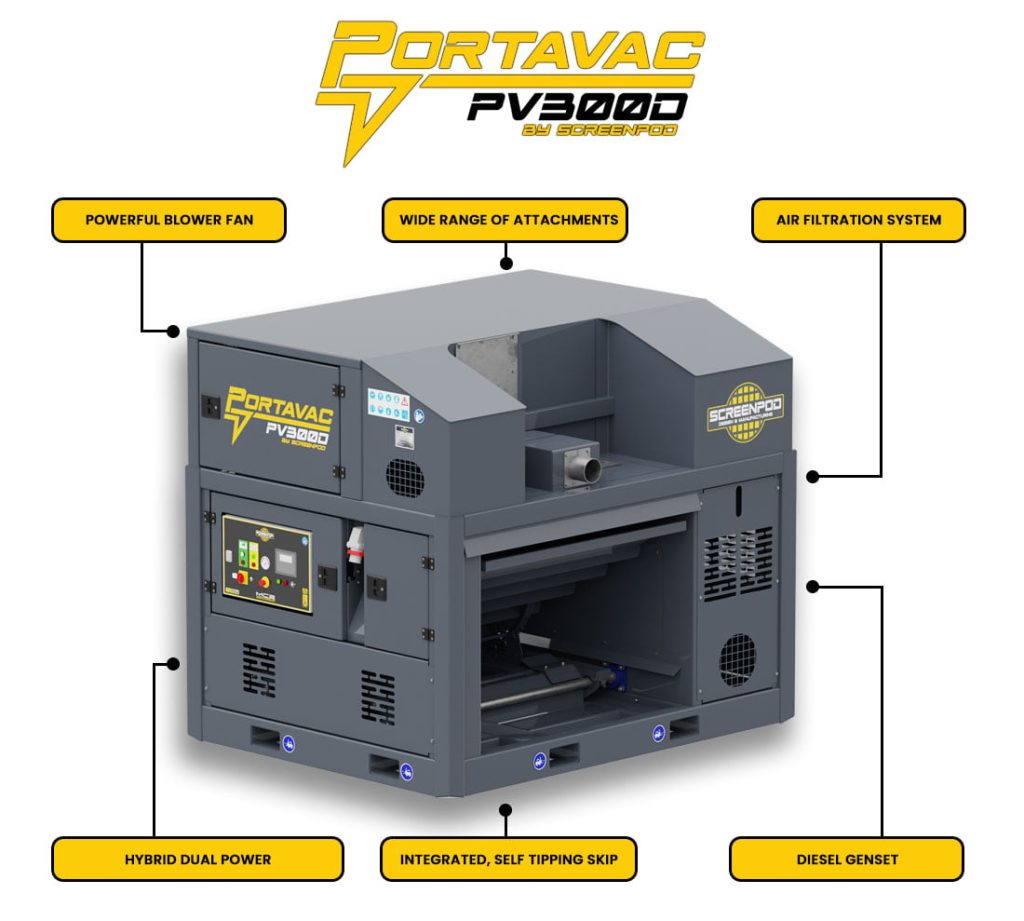

The Screenpod PV300D is a compact yet powerful self-contained industrial vacuum designed for demanding site applications. Supplied with a wide range of attachments, the unit offers excellent mobility and is capable of collecting materials ranging from fine dust to larger debris in both indoor and outdoor environments. A high-capacity integrated skip allows for efficient material collection and can be emptied quickly and safely using a forklift.

PORTAVAC PV300d

Designed to handle a wide range of materials across multiple industrial and site applications

Dual power capability, allowing operation via the onboard generator or an external power supply

Powered by an 18.4 kW (25 HP) EU Stage V / EPA Tier 4 Final Caterpillar diesel engine

Fuel-efficient engine design with no after-treatment or AdBlue requirement

Large-capacity fuel tank with level gauge and easily accessible filler

Integrated 32 Amp three-phase power connection for external supply use

High-capacity blower fan delivers strong, long-range suction performance

Capable of collecting materials from fine dust through to debris up to 40 mm

High-capacity integrated skip enables efficient material collection

Skip fitted with a built-in tipping mechanism for controlled discharge

Raise and lower system simplifies skip removal and refitting

Intuitive control interface for straightforward operation, including an emergency stop

Advanced air filtration system captures up to 99.7% of airborne particulates

Replaceable bag and HEPA filter elements for simple routine maintenance

Compatible with a wide selection of attachments and hose diameters

Long, flexible hoses provide extended reach into confined or difficult areas

Designed for low operating costs with minimal ongoing maintenance

Compact, low-noise design supports easy transport and use on active sites

Access doors and removable panels allow convenient servicing

Suitable for both indoor and outdoor use in demanding environments

benefits:

Significantly reduces employee exposure to dust, supporting safer working conditions

Keeps dust contained within the unit, preventing airborne release

Helps minimise dust and debris build-up on machinery, reducing wear and unplanned downtime

Maintains a cleaner, more organised working environment with less visible dust and waste

Provides a faster and more efficient alternative to manual cleaning methods

Simplifies routine housekeeping tasks, reducing labour time and effort

Can help lower cleaning, maintenance, and operational costs

Enables effective cleaning in areas that are difficult to access using conventional methods

Capable of handling larger and heavier materials than standard vacuum systems

Allows materials to be recovered quickly for reuse or recycling

Designed for easy and controlled emptying with minimal manual handling

CLEAN-UP APPLICATIONS:

Wood recycling and timber processing operations

Construction and demolition waste processing facilities

Quarries and aggregate production sites

Cement and concrete manufacturing plants

Pharmaceutical and food processing environments

Brick, block, and tile manufacturing facilities

Glass recycling and production plants

Lime and gypsum production sites

Grain processing and agricultural operations

Recycling yards and materials recovery facilities

Mining and mineral extraction operations

Active demolition projects

Ports, docks, and ship unloading operations

Steel mills, foundries, and metal processing plants

Asphalt production facilities

Pulp and paper manufacturing plants

Fertiliser production sites

Power station maintenance and industrial shutdown works

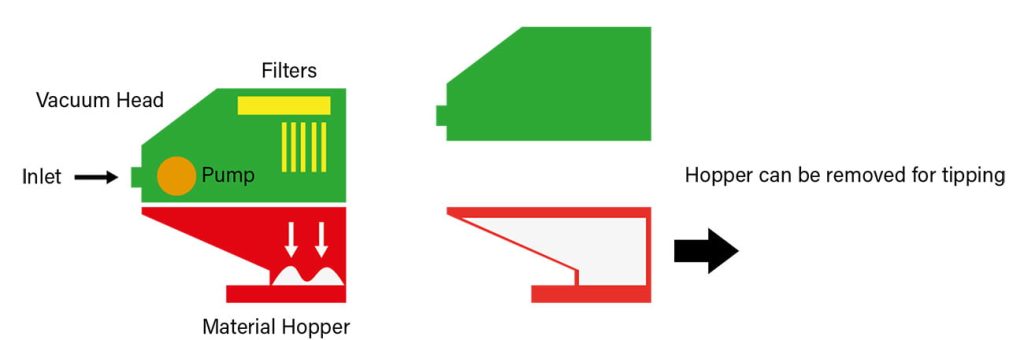

HOW IT WORKS:

The system is made up of two main components: the primary vacuum unit and a removable collection hopper, often referred to as the drop hopper. When in position, the hopper fits securely against the main body to form an airtight seal.

During operation, a high-powered blower fan within the main unit creates a strong vacuum inside the hopper. A hose is connected to the front of the machine via a coupling and can be fitted with a range of attachments, allowing dust and debris to be collected in a similar way to a conventional vacuum system.

As suction is generated, material is drawn through the hose and into the machine, where it drops directly into the hopper. Debris continues to collect until the hopper reaches capacity. Any fine airborne dust is captured by the integrated air filtration system before air is discharged.

Once full, the hopper can be easily removed and emptied using the built-in tipping mechanism. After emptying, the hopper is refitted, allowing the vacuum to return to operation with minimal downtime.

Speak to our team to discuss whether this industrial vacuum solution is right for your site and to explore hire or purchase options.

PORTAVAC PV300D

The Screenpod PV300D industrial vacuum is a powerful, self-contained cleaning and material recovery solution designed for demanding industrial, construction, and processing environments. Built to operate reliably in challenging site conditions, the Screenpod PV300D industrial vacuum provides an efficient way to collect dust, debris, and bulk materials while supporting safer, cleaner, and more productive operations.

The Screenpod PV300D industrial vacuum is particularly well suited to sites where dust and debris build up around production equipment, processing lines, or high-traffic areas. Its compact yet robust design allows it to operate effectively in both indoor and outdoor environments, making it a versatile solution for a wide range of applications. From fine dust and powders to larger debris, the PV300D is capable of handling varied materials without compromising performance.

At the core of the Screenpod PV300D industrial vacuum is a high-capacity blower fan that delivers strong, long-range suction. Material is drawn into the unit through flexible hoses connected to the front of the machine, which can be fitted with a wide selection of attachments to suit different tasks. As debris is collected, it is deposited into the integrated skip, allowing material to be contained safely and efficiently during operation.

A key advantage of the Screenpod PV300D industrial vacuum is its dual power capability. The unit can operate using its onboard diesel generator or be connected to an external power supply when required. This flexibility makes the PV300D suitable for sites with varying power availability, including remote locations where access to mains power may be limited. The fuel-efficient diesel engine is designed to meet modern emissions standards while avoiding the need for AdBlue or after-treatment systems.

The integrated high-capacity skip allows the Screenpod PV300D industrial vacuum to operate for extended periods without frequent emptying. When full, the skip can be removed and emptied quickly using the built-in tipping mechanism, typically with forklift assistance. This reduces manual handling, minimises downtime, and allows cleaning operations to be completed efficiently.

Dust containment is a key strength of the Screenpod PV300D industrial vacuum. An advanced air filtration system captures up to 99.7% of airborne particulate matter during operation, helping to prevent dust from being released back into the working environment. This supports improved air quality on site and reduces exposure risks for operatives, particularly in environments where fine dust presents a health and safety concern.

The Screenpod PV300D industrial vacuum is designed with ease of use in mind. Simple, intuitive controls allow operators to deploy the machine quickly with minimal training, while long, flexible hoses provide extended reach into confined or difficult-to-access areas. Access doors and removable panels allow straightforward servicing and maintenance, helping to keep the unit operating reliably on busy sites.

Durability is another key feature of the Screenpod PV300D industrial vacuum. The machine is constructed from robust steel with a hard-wearing protective coating, making it suitable for harsh industrial environments. Its compact footprint and controlled noise output also make it practical for use in areas where space or noise restrictions apply.

The Screenpod PV300D industrial vacuum is commonly supplied on a hire basis, offering a flexible and cost-effective solution for projects with temporary or variable cleaning requirements. Hiring allows site operators to access a high-performance industrial vacuum without the capital cost of ownership, while benefiting from maintained, site-ready equipment. This makes the PV300D ideal for shutdown cleaning, planned maintenance, spill response, or short-term projects requiring effective dust and debris control.

In addition to improving site cleanliness, the Screenpod PV300D industrial vacuum supports wider operational and environmental objectives. Removing dust and debris at source helps protect machinery from build-up, reducing wear and the risk of breakdowns. It also contributes to safer working environments and supports compliance with health, safety, and environmental standards.

For operations seeking a powerful, flexible, and reliable industrial vacuum available on a hire basis, the Screenpod PV300D industrial vacuum offers a proven solution for managing dust and debris efficiently across a wide range of site conditions.