For effective dust suppression on active sites, dust cannons provide a high-performance solution for controlling airborne dust without the need for permanent installation. These systems help reduce dust-related health risks and improve air quality across a wide range of applications, including recycling facilities, demolition works, quarries, ports, and bulk material handling areas.

Dust cannons are available in static, trailer-mounted, and tracked formats, making them well suited to hire for short-term projects or changing site conditions. Their compact, transportable design allows for quick setup and easy repositioning as works progress, while low maintenance requirements and efficient operating costs make hire a practical and flexible option. Each unit is operated through a clear, intuitive control system, ensuring reliable dust control throughout the hire period.

S65 Static Dust Cannon

Delivers effective dust suppression with a coverage range of up to approximately 45 metres

Produces a fine mist via precision spray nozzles to capture airborne dust particles

Adjustable water flow to suit varying dust levels and site conditions

Capable of operating from either a mains water connection or an on-site water tank

Fitted with a high-capacity water pump and integrated run-dry protection for safe, reliable operation

Includes an inlet water filter with a removable element to support routine maintenance

Drain valves provided for straightforward system emptying when required

Powered by a high-speed fan and motor for consistent mist projection over large areas

Operates from a 32A power supply, with options available for 50Hz or 60Hz systems

Supplied with a clearly laid-out electrical control panel for simple and intuitive operation

Offers up to 350° rotation, with automatic slewing and adjustable stops to control the sweep angle

Features electrically operated elevation for accurate mist direction

Mounted on a fork-pocket base frame with lifting eyes, allowing safe and efficient movement around site

Uses a claw-type inlet connector for quick and secure water supply connection

benefits:

Helps reduce health and safety risks associated with exposure to airborne dust

Improves overall air quality for workers and surrounding areas

Suppresses fine dust particles before they can spread across the site

Supports protection of the local environment and nearby receptors

Enhances visibility on-site, particularly around active plant and machinery

Minimises the formation of dust plumes around operating equipment

Helps reduce the likelihood of dust-related complaints from neighbouring properties

Can lower cleaning, maintenance, and downtime costs caused by excessive dust

APPLICATIONS:

Timber recycling facilities and wood processing or production plants

Construction and demolition waste processing operations

Material recycling yards and waste sorting facilities

Mining and mineral extraction operations

Concrete batching, mixing, and production plants

Active demolition sites and structural removal projects

Landfill sites and waste management operations

Ports, docks, and ship unloading facilities handling bulk materials

Scrap metal processing yards and steel manufacturing facilities

Live events, outdoor venues, and selected industrial cooling applications

HOW IT WORKS:

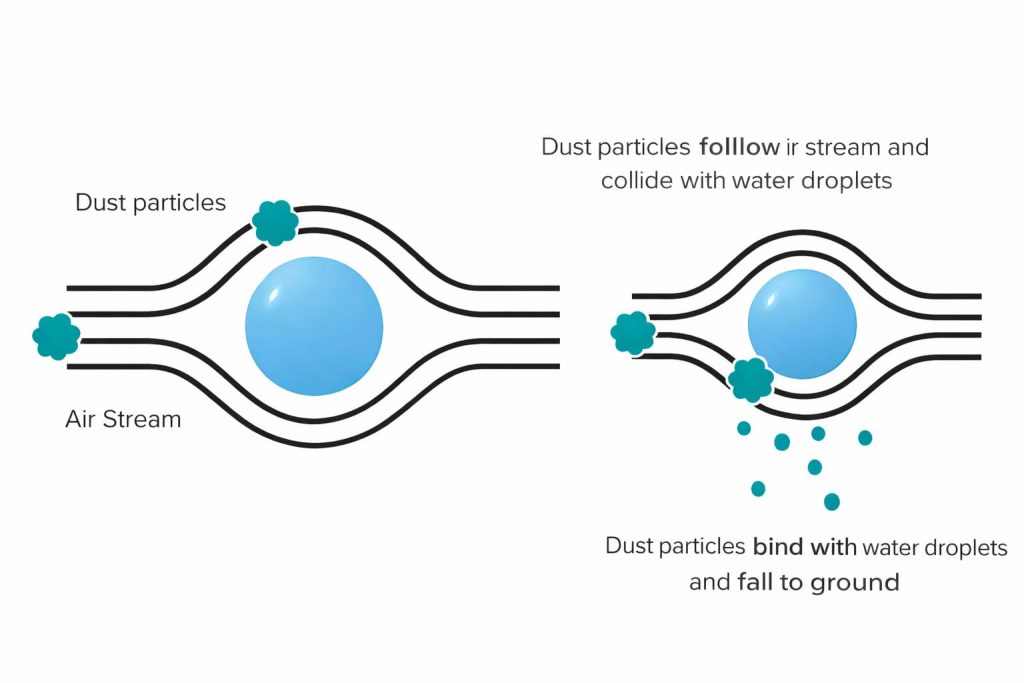

Water is atomised through specially engineered nozzles to produce a fine mist. A high-velocity fan creates airflow that carries this mist evenly across the required area.

As the mist moves through the air, the atomised water droplets interact with airborne dust particles. These particles bind to the droplets, increasing their weight and causing them to settle safely to the ground. This process removes dust from the air and provides effective suppression of airborne emissions.

Speak to our team to discuss whether this dust suppression solution is right for your site and to explore hire or purchase options.

S65 Static Dust Cannon

The S65 Static Dust Cannon is a high-output dust suppression solution designed for fixed installations where wide-area, continuous dust control is required. Commonly used across quarries, recycling facilities, demolition sites, ports, concrete production plants, and bulk material handling operations, the S65 Static Dust Cannon delivers powerful and reliable suppression of airborne dust in demanding industrial environments.

The S65 Static Dust Cannon is particularly well suited to locations where dust generation is constant and concentrated around specific processes, such as crushing, screening, loading, stockpiles, and material transfer points. Installed in a fixed position, the unit provides consistent mist coverage across large working areas, helping to suppress airborne dust before it can disperse across the site or beyond its boundary. This supports improved air quality, safer working conditions, and reduced environmental impact.

At the core of the S65 Static Dust Cannon is a proven dust suppression process using atomised water mist. Fine droplets are produced through specially designed spray nozzles and projected into the air by a high-powered fan. As airborne dust particles collide with the mist, they bind to the droplets, increasing in weight and settling safely to the ground. This process removes dust from the air effectively while avoiding excessive wetting of materials, plant, or working surfaces.

One of the key advantages of the S65 Static Dust Cannon is its ability to deliver high-capacity dust suppression from a permanent or semi-permanent installation. Unlike mobile or trailer-mounted systems, the static configuration is ideal for sites where dust sources remain in the same location over extended periods. Its wide throw distance and controlled rotation allow operators to target dust emissions efficiently, making it suitable for large processing areas and open industrial environments.

The S65 Static Dust Cannon is commonly supplied on a hire basis, offering a cost-effective solution for sites that require powerful dust control without committing to equipment ownership. Hiring allows operators to deploy a high-output dust suppression system for the duration of a project, production phase, or operational period, while benefiting from maintained, site-ready equipment. This flexibility is particularly valuable for long-running projects, seasonal operations, or facilities with changing production demands.

Designed with ease of use in mind, the S65 Static Dust Cannon features intuitive controls that allow operators to adjust rotation, elevation, and water output to suit site-specific conditions. Once configured, the system can operate continuously with minimal intervention, helping to maintain consistent dust suppression throughout the working day. Its robust construction and low maintenance requirements further support reliable performance throughout the hire period.

In addition to improving on-site working conditions, the S65 Static Dust Cannon plays an important role in supporting environmental compliance and community relations. Uncontrolled dust can reduce visibility, increase health risks for workers, and lead to complaints from neighbouring properties. By installing a dedicated static dust suppression system, site operators can demonstrate proactive dust management and reduce the likelihood of disruption or enforcement action.

The S65 Static Dust Cannon is widely used across a range of sectors, including quarrying, recycling, demolition, ports, concrete production, and waste management operations. Its combination of high-output performance, wide coverage, and fixed installation makes it a dependable solution for sites requiring consistent and effective dust suppression at scale.

For operations seeking a powerful static dust control solution with flexible hire options, the S65 Static Dust Cannon offers a proven approach to managing airborne dust. Whether used as a standalone system or as part of a wider dust control strategy, it delivers reliable performance that supports safer working environments, improved air quality, and stronger site compliance.